As we all know Barry is the expert on buildings and creating amazing 1/72 scale BF-109s/

Here is his build comments on the Eduard BF109F

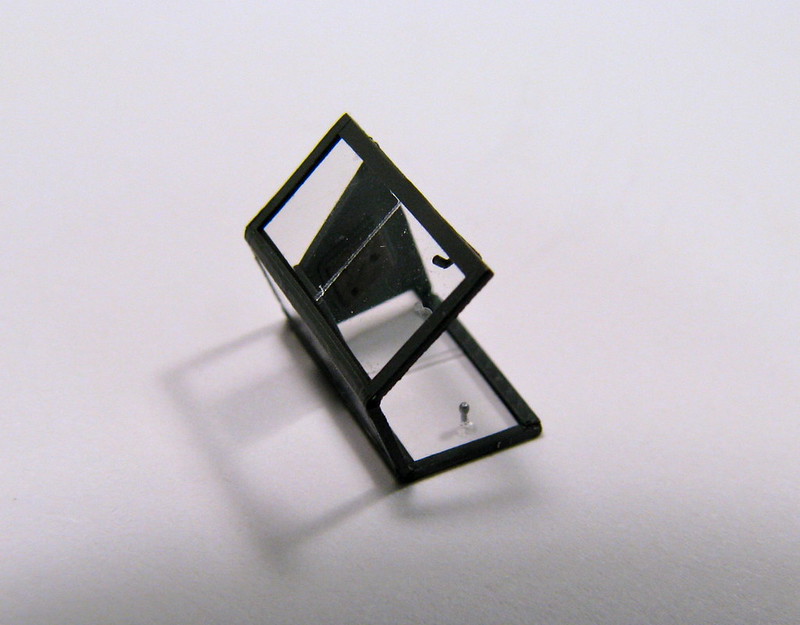

1. Painting the exterior of the gun troughs with the camo color before assembling the fuselage halves. This allows you to paint the guns before inserting them (with the unusual two part contraption that is the Eduard solution to gun alignment). I'm being a bit harsh here; I had a rather difficult time with the first 109 F I built, but these three were much easier. I even used the Eduard 3D. printed guns on one of the models. Although time saving and foolproof, it is not necessary. If you are VERY careful drilling out the kit guns, which is difficult given the soft plastic, you can achieve comparable results. But, as I said, the aftermarket part is foolproof.

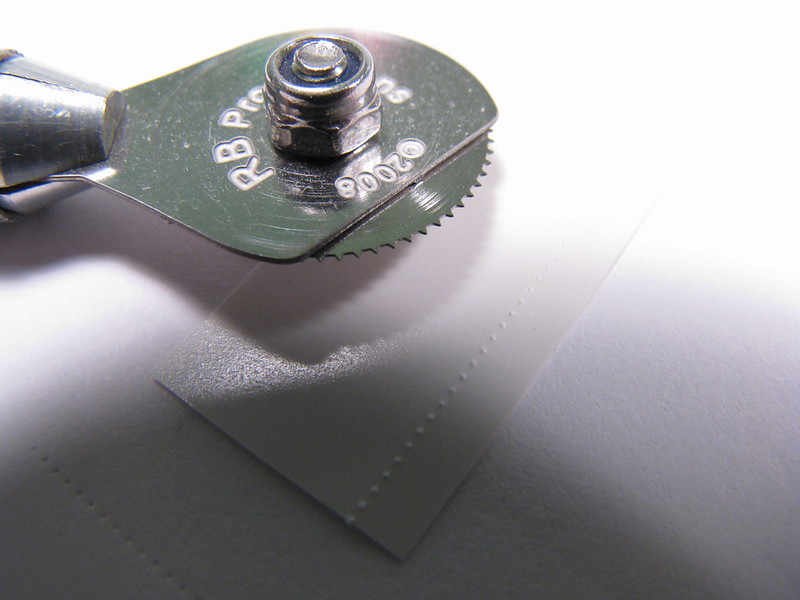

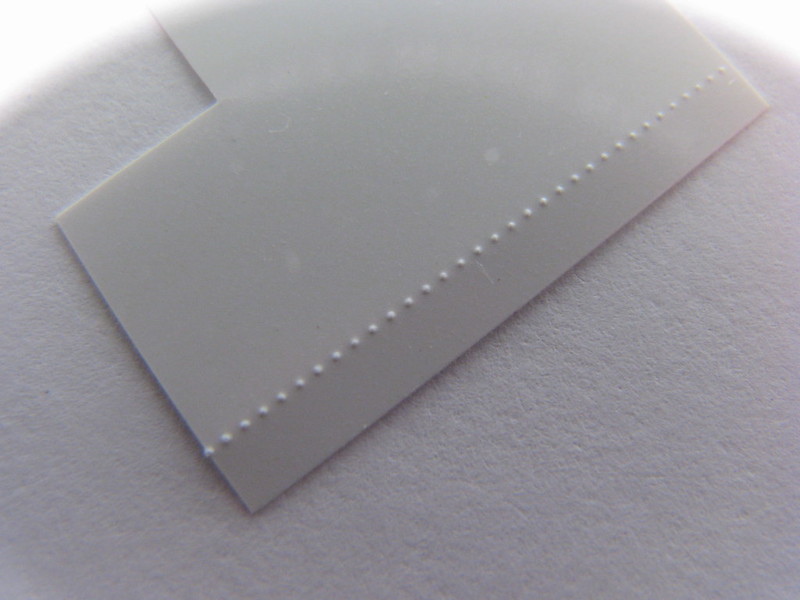

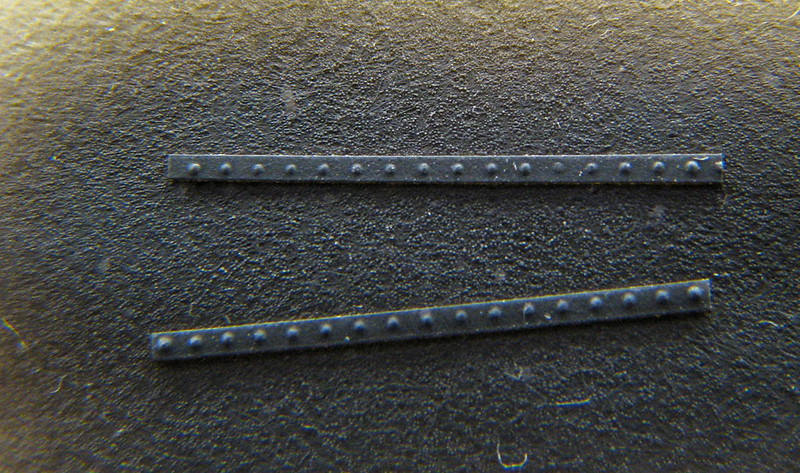

2. Paint the wheel well area on the outside of lower wing first. Then separately paint the wheel well pieces and weather to taste. Do the same with the interior of the upper wing parts. Finally assemble all three. Here again, on one of the models I used Eduard's 3D printed inserts. This time they are definitely better than the kit parts. The stitching of the leather boots is beautifully rendered. They are also a bit more flexible which helps - because at least for me, the plastic inserts resist setting into their grooves perfectly. I used small clamps and 5-minute epoxy the tack on one side first. After that set up, I removed the clamps and smeared more epoxy to firmly secure that side. Finally I repeated the process on the other end of the well. Several days of work, but there were no excess glue smears and the joint was very secure. I did find that the wells need some sanding to allow the upper wing to fit. This was easier on the 3D printed set. This may be operator error. Regardless, it would make sense to test fit and sand them down before gluing them to the lower wing. Notes made on the instruction sheet for future builds.

3. The clear wing tip lights are beautiful, but fiddly to the max. I drilled a hole in the back and forced some paint into it to represent the bulb. Per my usual habit, I then painted the rear of this part black, as well as the area of the wing tip where they will be inserted. A tiny drop of white glue held them in place temporarily. Then I applied black superglue (great stuff) to fill the joints. After setting with accelerator the excess was removed with a Q-tip and debonder. This worked better than my previous methods.

4. Frustratingly, all three models suffered from FWS - Flat Wing Syndrome. Dry fitting the wings resulted in the fuselage sides pushing out the upper edge of the wings forcing them down. Again, this may be user error, but it happened with all three kits. No real problem, I just sanded down the fuselage wing roots a bit, allowing the wings to assume the proper dihedral. This may have been prevented by taping the lower wing to the fuselage and dry fitting the upper wings, but I didn't expect the issue to come up. Again, notes made on instructions for next time.

5. The horizontal stab is a single piece that slots into the fin, a nice touch. But the fit is extremely tight, to the point that if you dry fit it, good luck with getter it off again. I used a very thin file to open the fin slot a bit. Also note that there is a tiny mold defect on one of the elevators. Fortunately, this is intended to be placed on the bottom.

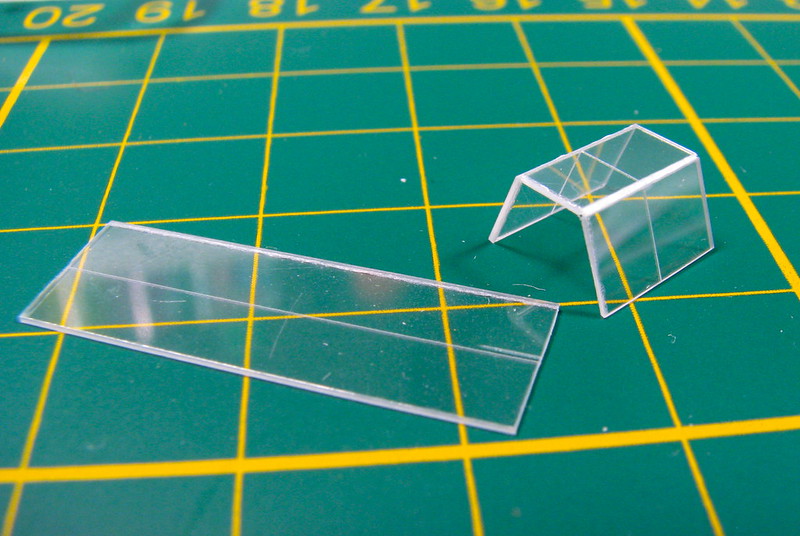

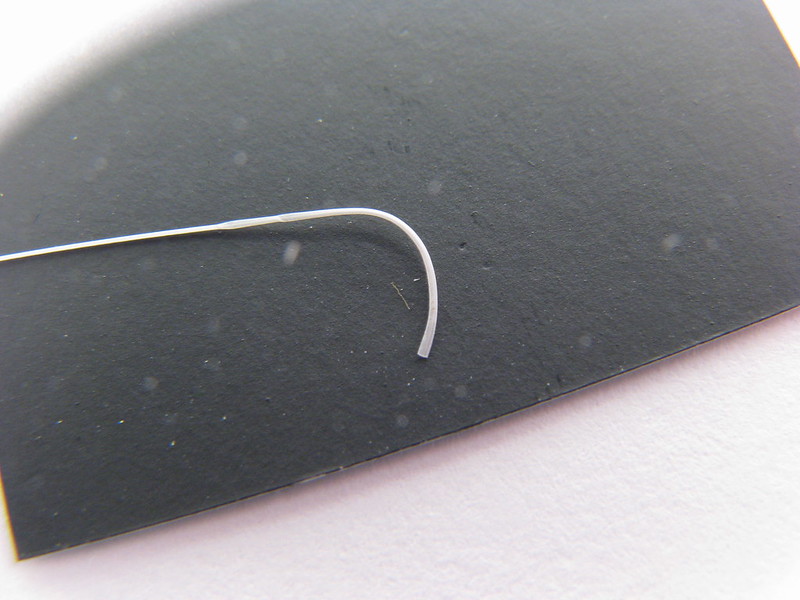

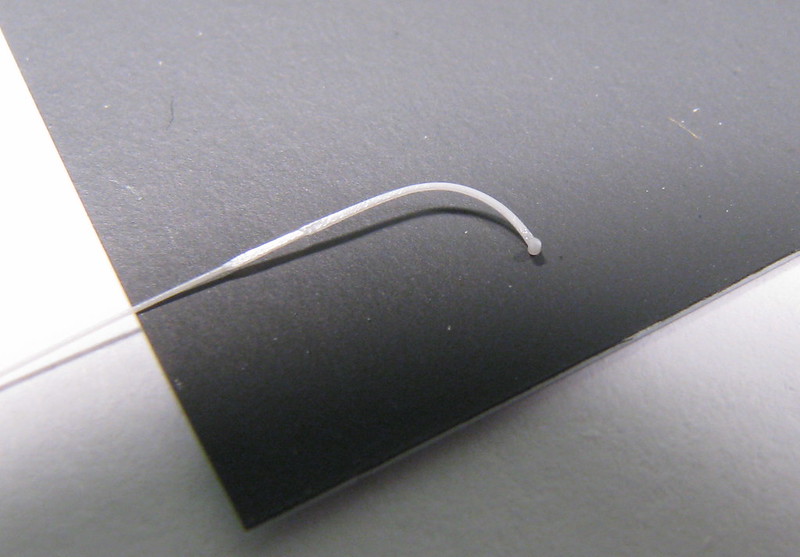

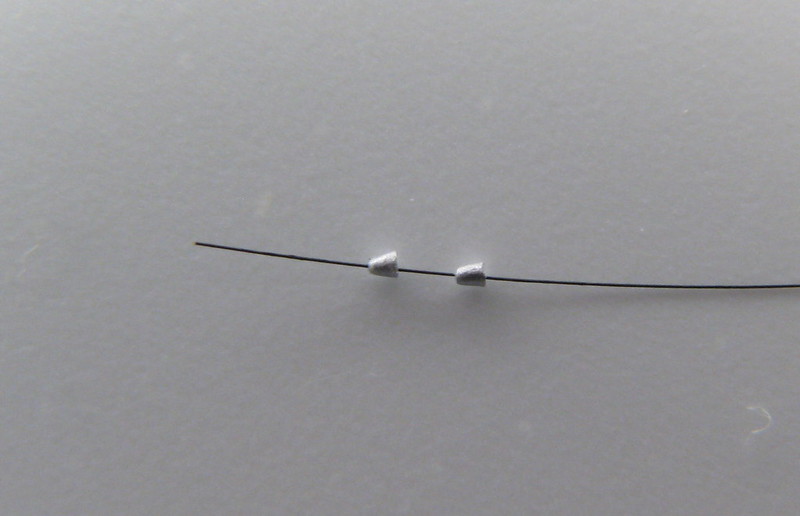

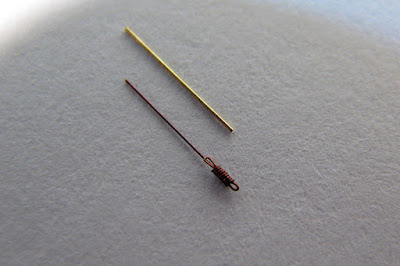

6. And finally - the fuel line through the cockpit. Eduard uses a clear part to represent this tube. An excellent concept, but ... clear plastic is very brittle. I have broken four of them. If you're very careful you can glue them back together, for a bit. Regardless, the limits of molding and practicality intervene and the tube appears too big when painted yellow. In the future I may keep the clear central section and form the remainder of the tube from thin solder. To tone them down, I used a lighter shade of yellow.

Here are a few more photos showing progress to this point. No clues as to the aircraft to be represented, but at least one of them is obvious!

I hope these tips will prove useful to first time 109 F builders, but then again, some may be purely user errors.